PROJECT

PROJECT

In this client's factory, which has a chip mounter line, they carry out the process of mounting semiconductors onto boards. A shelf was placed next to the line for reel materials of semiconductors, and about 10,000 types of materials were stored there.

Every day, workers would pick and transport materials visually while comparing them with a withdrawal list, and there were often mistakes such as picking errors. Detailed management such as first-in-first-out was also needed.

Ten people worked on this task daily, but the production efficiency was never satisfactory due to the constant walking, standing, and squatting inside the space. As the number of production items increased, the storage space also expanded, and the sense of the problem grew.

Additionally, during inventory checks, there was a need to confirm each material individually, requiring a full day's worth of labor.

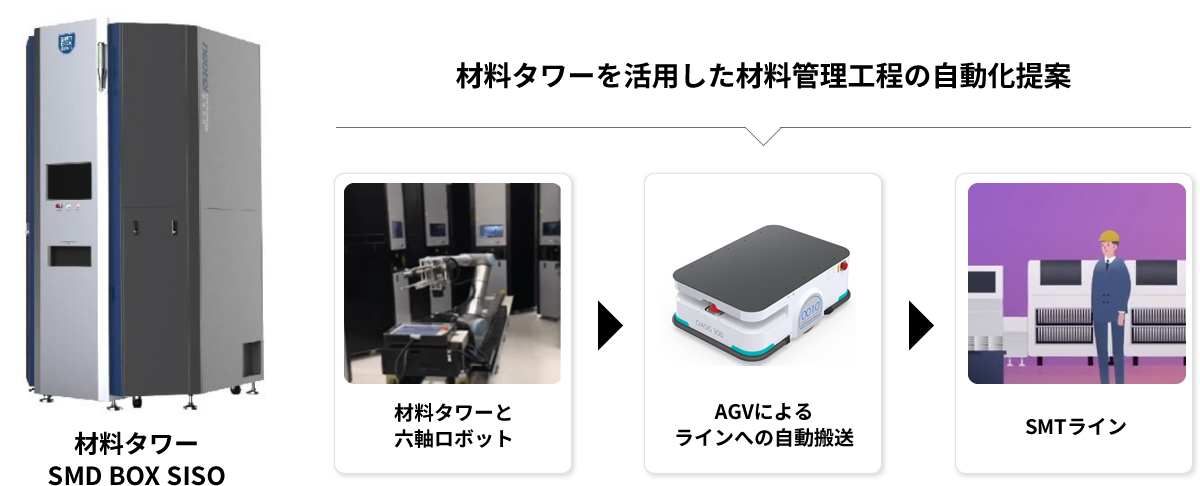

We introduced a material tower and proceeded with the automation of material storage and retrieval operations.

First, based on the data received from the client, we calculated the expected daily number of reel storage and retrievals. Then, we compared the labor hours between using the material tower and manual operation, and calculated the type and number of material towers needed, considering the investment payback period.

By introducing the material tower, we automated the storage and retrieval operations.

In this case, we introduced eight units of single storage and retrieval type SMD BOX SISO. We installed them in a cell format, building a system where one person can easily carry out the storage and retrieval operations.

Eventually, by introducing a six-axis robot and conveyor line, we realized automatic storage and retrieval operations for materials in the SMD BOX without human intervention.

Workers reduced from 10 to 2 (8 personnel reduction)

Reduction in inventory checking labor hours

The goal was complete automation, but suddenly introducing multiple devices can increase the load on the control side, making mid-course corrections difficult. In this case, we started with the introduction of only the material tower, eliminating the wastes of ""finding target part numbers,"" ""walking around the warehouse,"" and ""checking materials."" Once the operation began to run smoothly, we introduced a six-axis robot and a conveyor line to achieve full automation.

We conducted a preliminary analysis by gathering information such as the expected monthly storage and retrieval volume, types of materials, inventory checking labor hours, current number of workers, and cost-effectiveness. Then we determined the possible investment amount and the optimal material tower selection. Neotel Technology, the manufacturer of the material towers, offers a wide lineup and customization, making it possible to provide the best equipment for the customer.

The step-by-step approach to automation allowed for careful implementation and control, while the detailed analysis and customization ensured that the solution was tailored to the customer's specific needs. By identifying and eliminating inefficiencies and gradually integrating technology, LOGITO provided a solution that significantly improved efficiency and reduced labor.

LOGITO is a logistics automation solution provided by DJK.

Singapore

DAIICHI JITSUGYO ASIA PTE. LTD.

SMT Systems Dept.

TEL:+65-6338-3732

1 Kaki Bukit View #04-30/31 Techview, Singapore 415941

Thailand

DAIICHI JITSUGYO (THAILAND) CO., LTD.

Electronics Dept.

TEL:+66-2-796-1555

33/4 The 9th Towers Grand Rama 9, Tower B, TNB05, 23rd Floor, Rama 9 Road, HuayKhwang, Bangkok 10310 Thailand

Malaysia

DAI-ICHI JITSUGYO (MALAYSIA) SDN. BHD.

Electronics Dept.

TEL:+60-3-2070-6913

Box No.80, 31st Floor, UBN Tower,No.10 Jalan P. Ramlee 50250, Kuala Lumpur, Malaysia

Philippines

DAIICHI JITSUGYO (PHILIPPINES), INC.

Electronics Dept.

TEL:+63-2-8887-1588

Unit No.1204, Frabelle Business Center, 111 Rada Street, Legaspi Village, Makati City 1229, Philippines

Indonesia

PT. DJK INDONESIA

SMT-Dept.

TEL:+62-21-573 9370

Mid Plaza 2, 14th floor Jalan Jenderal Sudirman Kavling 10-11, Jakarta 10220, Indonesia

India

DAIICHI JITSUGYO INDIA PVT. LTD.

Electronics Dept.

TEL:+91-12-4426-6080

Unit No.002, Ground Floor, Time Tower, M.G. Road, Gurgaon, Haryana 122002, India

Vietnam

DAIICHI JITSUGYO (VIETNAM) CO., LTD.

SMT Dept.

TEL:+84-24-3766-5990

6th Floor, Detech Tower, 8 Ton That Thuyet Street, My Dinh 2 Ward,Nam Tu Liem District, Hanoi City, Vietnam

Mexico

DJK GLOBAL MEXICO, S.A. DE C.V.

TEL:+52-442-217-4975

Avenida Antea No. 1090, Piso 3, Oficina 308, Edificio Business Park II, Colonia Jurica, Queretaro, Queretaro C.P.76100, Mexico

Germany

DJK EUROPE GMBH

TEL:+49-6196-776-14-18

Mergenthalerallee 79-81, D-65760 Eschborn, Germany

Taiwan

DJK (TAIWAN) CORP.

Electronics Team

TEL:+886-2-2327-8831

12F-1, 23, Sec. 1, Bade Road, Taipei 10058, Taiwan

Korea

DAIICHI JITSUGYO CO., LTD. Seoul Branch

TEL:+82-2-551-2500

3003, Trade Tower, 511, Yeongdong-daero, Gangnam-gu, Seoul 06164, Korea

We will contact you within one day after receiving your inquiry, excluding weekends and national holidays.

Please be careful to enter correct contact information.