PROJECT

PROJECT

In this customer's factory, there are transactions with over 100 suppliers, and more than 400 types of parts delivered daily in reusable containers. After distributing the parts to the production line, the emptied reusable containers need to be sent back to the suppliers, a sorting task that required significant effort.

Ten people were working daily on this task, with the number of empty containers sent back being 22,000 per day, and exceeding 30,000 per day during peak times. Additionally, because the arrival order of the reusable containers was irregular, it was necessary to store them until a certain number accumulated, and securing that storage space was also required.

We analyzed the distribution data for each reusable container. Although irregular, a detailed analysis made it possible to identify trends and groupings. By analyzing not only the daily distribution numbers but also the numbers for each reusable container, we were able to consider the optimal solution.

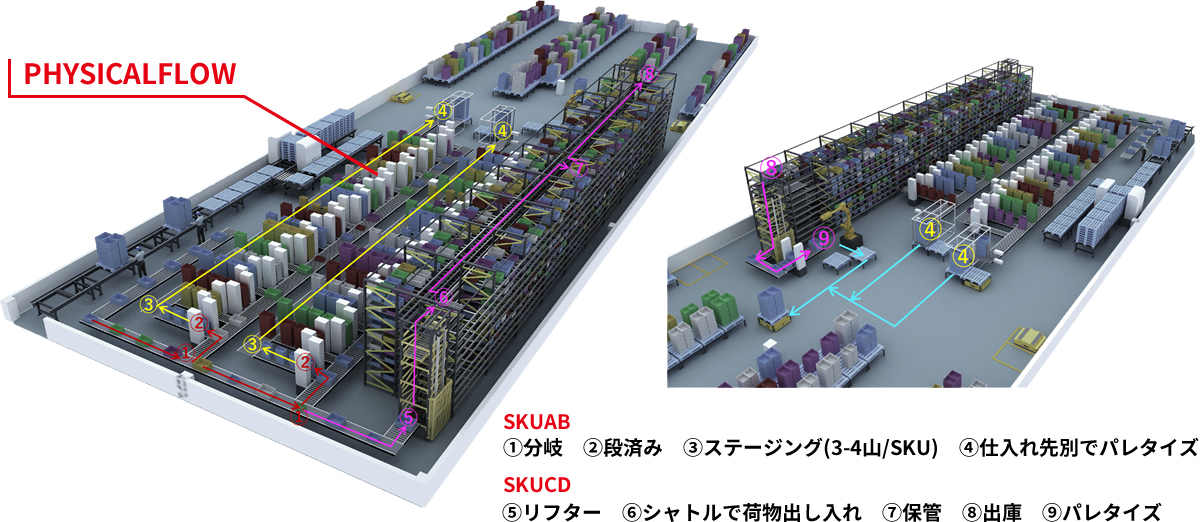

Based on the analysis data, we proposed management using an automated shuttle-style warehouse. Additionally, we proceeded with simultaneous introduction of AGVs, stacking devices, palletizing robots, and image processing (automatic box recognition) devices for warehouse import and export.

Since the objective was to reduce labor, this was accomplished by introducing automated warehouses, AGVs, and palletizing robots. Furthermore, we were able to simultaneously eliminate the initial sorting process for reusable containers and achieve space-saving by introducing an automated warehouse.

Reduction of workforce from 10 to 3 people (7 people reduction)

Elimination of initial sorting process

20% reduction in workspace

We can provide the optimal solution to customers by not only introducing simple equipment but also combining various devices. By selecting devices from various manufacturers, such as palletizing robots, AGVs, and automated warehouses, we make proposals that capitalize on each device's strengths.

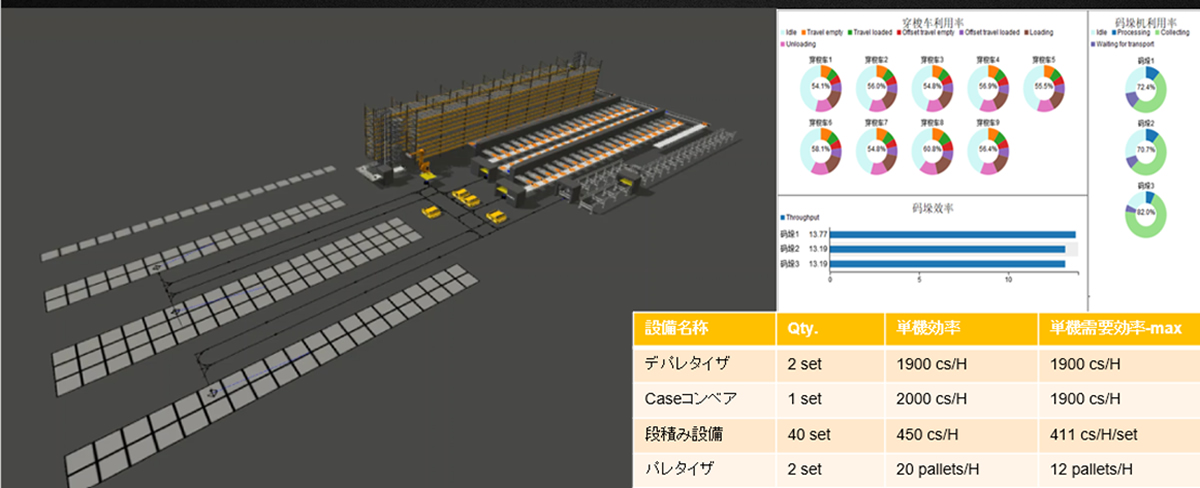

By using simulation software, we share the pre-implementation image with the customer. It allows for a complete understanding of the required space, layout, etc., within the customer's organization. Moreover, we can quantify the effects after implementation and demonstrate the investment return needed at the time of application approval.

LOGITO is a logistics automation solution provided by DJK.

Singapore

DAIICHI JITSUGYO ASIA PTE. LTD.

SMT Systems Dept.

TEL:+65-6338-3732

1 Kaki Bukit View #04-30/31 Techview, Singapore 415941

Thailand

DAIICHI JITSUGYO (THAILAND) CO., LTD.

Electronics Dept.

TEL:+66-2-796-1555

33/4 The 9th Towers Grand Rama 9, Tower B, TNB05, 23rd Floor, Rama 9 Road, HuayKhwang, Bangkok 10310 Thailand

Malaysia

DAI-ICHI JITSUGYO (MALAYSIA) SDN. BHD.

Electronics Dept.

TEL:+60-3-2070-6913

Box No.80, 31st Floor, UBN Tower,No.10 Jalan P. Ramlee 50250, Kuala Lumpur, Malaysia

Philippines

DAIICHI JITSUGYO (PHILIPPINES), INC.

Electronics Dept.

TEL:+63-2-8887-1588

Unit No.1204, Frabelle Business Center, 111 Rada Street, Legaspi Village, Makati City 1229, Philippines

Indonesia

PT. DJK INDONESIA

SMT-Dept.

TEL:+62-21-573 9370

Mid Plaza 2, 14th floor Jalan Jenderal Sudirman Kavling 10-11, Jakarta 10220, Indonesia

India

DAIICHI JITSUGYO INDIA PVT. LTD.

Electronics Dept.

TEL:+91-12-4426-6080

Unit No.002, Ground Floor, Time Tower, M.G. Road, Gurgaon, Haryana 122002, India

Vietnam

DAIICHI JITSUGYO (VIETNAM) CO., LTD.

SMT Dept.

TEL:+84-24-3766-5990

6th Floor, Detech Tower, 8 Ton That Thuyet Street, My Dinh 2 Ward,Nam Tu Liem District, Hanoi City, Vietnam

Mexico

DJK GLOBAL MEXICO, S.A. DE C.V.

TEL:+52-442-217-4975

Avenida Antea No. 1090, Piso 3, Oficina 308, Edificio Business Park II, Colonia Jurica, Queretaro, Queretaro C.P.76100, Mexico

Germany

DJK EUROPE GMBH

TEL:+49-6196-776-14-18

Mergenthalerallee 79-81, D-65760 Eschborn, Germany

Taiwan

DJK (TAIWAN) CORP.

Electronics Team

TEL:+886-2-2327-8831

12F-1, 23, Sec. 1, Bade Road, Taipei 10058, Taiwan

Korea

DAIICHI JITSUGYO CO., LTD. Seoul Branch

TEL:+82-2-551-2500

3003, Trade Tower, 511, Yeongdong-daero, Gangnam-gu, Seoul 06164, Korea

We will contact you within one day after receiving your inquiry, excluding weekends and national holidays.

Please be careful to enter correct contact information.